LED Explosion Proof Lighting for Hazardous Industrial Environments

Explosion proof LED lighting is engineered for hazardous industrial environments where flammable gases, vapors, combustible dust, or ignitable fibers may be present. These specialized fixtures are designed to contain internal ignition sources and prevent sparks, arcs, or heat from igniting surrounding atmospheres. Certified explosion proof lighting is commonly required in facilities classified under NEC Class I, Class II, and Division 1 or Division 2 hazardous location standards.

Explosion proof LED lighting is widely specified in oil and gas facilities, chemical plants, refineries, manufacturing operations, grain processing facilities, and other regulated industrial environments. These fixtures enhance workplace safety, support regulatory compliance, and provide durable, energy-efficient illumination in extreme operating conditions.

This guide explains when explosion proof lighting is required, key certifications and technical specifications, and how to select the appropriate LED fixtures for hazardous location applications.

What Is Explosion Proof LED Lighting?

Explosion proof LED lighting refers to specially engineered lighting fixtures designed for installation in hazardous locations where flammable gases, vapors, combustible dust, or ignitable fibers may be present. These fixtures are constructed to contain any internal sparks, arcs, or heat generated by electrical components, preventing ignition of surrounding explosive atmospheres.

Contrary to common misunderstanding, explosion proof lighting does not prevent explosions from occurring. Instead, it is designed to contain a potential ignition source within the fixture housing. The enclosure is built with reinforced materials and precision-engineered seals so that if an internal ignition occurs, it cannot escape and ignite external hazardous materials.

Explosion proof LED lighting is required in areas classified under the National Electrical Code (NEC) as Class I, Class II, or Class III hazardous locations. These classifications define the type of combustible material present, while Divisions (Division 1 or Division 2) indicate the likelihood of that material being present under normal operating conditions.

Modern explosion proof LED fixtures combine this containment design with the efficiency, durability, and long service life of LED technology. Compared to traditional HID or fluorescent hazardous-location lighting, LED explosion proof fixtures offer lower energy consumption, reduced maintenance requirements, instant-on performance, and improved reliability in extreme temperatures.

Because hazardous location lighting must meet strict regulatory standards, certified explosion proof LED lighting is typically tested and labeled under UL844, ATEX, IECEx, or other recognized safety certifications, depending on regional requirements.

When to Use Explosion-Proof Lighting

Explosion-proof lighting is specified for environments where combustible materials may be present during normal or abnormal operating conditions, including:

-

Areas classified as hazardous locations under industrial safety standards

-

Facilities handling flammable gases, vapors, or combustible dust

-

Industrial processes involving chemicals, fuels, or volatile materials

-

Locations requiring code-compliant containment of ignition sources

-

Operations where fixture reliability is critical under harsh conditions

Explosion-proof fixtures are selected not for brightness alone, but for their ability to operate safely within classified environments

Explosion-Proof Fixture Types by Application

Hazardous industrial facilities deploy multiple explosion proof LED lighting fixture types depending on ceiling height, process layout, environmental exposure, and maintenance accessibility.

Industrial Process Areas

Long production corridors and equipment rows often utilize explosion-proof linear lighting to provide continuous, shadow-free coverage across work zones. Enclosed coating operations require certified explosion-proof paint spray booth lighting engineered for solvent-rich atmospheres and combustible vapor containment. Elevated structures and large manufacturing bays frequently rely on explosion-proof high bay lighting to deliver broad, uniform illumination from overhead mounting positions.

In tighter service areas where moisture resistance and particulate protection are critical, compact explosion-proof vapor-tight LED fixtures are commonly specified for durability and long-term performance.

Exterior & Circulation Zones

Hazardous facilities must also maintain safe visibility across exterior and transitional areas. Wide-area yards, tank farms, and perimeter zones are typically illuminated using explosion-proof LED flood lighting designed for long throw and high-output performance. Roadways and internal traffic routes may require purpose-built explosion-proof street lights capable of higher mounting heights and extended light distribution patterns.

Life-safety pathways, equipment rooms, and exit routes depend on certified explosion-proof exit signs to ensure code-compliant egress under all operating conditions.

Classification-Driven Selection

Lighting strategy in hazardous environments is ultimately governed by classification requirements. Areas where flammable atmospheres are present during normal operations require Class 1 Division 1 LED lighting, while locations with only occasional exposure may be served by Class 1 Division 2 rated systems.

International projects often introduce additional certification pathways, leading engineers to specify ATEX-certified explosion-proof LED lighting. Offshore platforms and aviation infrastructure may incorporate specialized systems such as explosion-proof helideck lighting, engineered for mission-critical reliability in extreme marine environments.

Certifications & Compliance Standards for Explosion Proof LED Lighting

Explosion proof LED lighting must comply with strict safety standards to ensure safe operation in classified hazardous locations. Regulatory requirements vary by region and industry, but all certified explosion proof fixtures are tested to confirm that they can contain internal ignition sources and prevent ignition of surrounding explosive atmospheres.

NEC Hazardous Location Classifications (United States)

In the United States, explosion proof lighting is governed by the National Electrical Code (NEC), which defines hazardous locations by Class, Division, and in some cases Zone.

-

Class I – Locations where flammable gases or vapors are present

-

Class II – Locations where combustible dust is present

-

Class III – Locations where ignitable fibers or flyings are present

Each class is further divided into:

-

Division 1 – Hazardous material is present under normal operating conditions

-

Division 2 – Hazardous material is present only under abnormal conditions

Explosion proof LED fixtures installed in these environments must be properly rated and labeled to match the classification of the area.

UL844 Certification

In North America, many explosion proof LED lighting fixtures are tested and listed under UL844, the standard for luminaires intended for hazardous locations. UL certification confirms that the fixture meets enclosure strength, thermal performance, and ignition containment requirements for its specified classification.

Proper labeling is critical. A compliant fixture will clearly display its Class, Division, and temperature rating.

ATEX & IECEx (International Standards)

For projects outside the United States, hazardous lighting may require compliance with ATEX (Europe) or IECEx (global certification framework).

-

ATEX certification is required for equipment used in explosive atmospheres within the European Union.

-

IECEx provides international conformity standards for explosive environments.

These certifications ensure that explosion proof LED lighting meets containment, material, and testing requirements appropriate for Zone-based classification systems.

Temperature Codes (T-Ratings)

Explosion proof LED lighting must also meet specific temperature classifications, commonly referred to as T-ratings (such as T4, T5, or T6). These ratings indicate the maximum surface temperature the fixture can reach during operation.

The T-rating must be lower than the ignition temperature of the surrounding hazardous material to ensure safe operation. Selecting the correct temperature class is a critical component of hazardous location compliance.

IP Ratings & Environmental Protection

While explosion proof certification focuses on ignition containment, many hazardous environments also require protection from moisture, dust, and corrosive elements. Explosion proof LED fixtures often include IP66 or IP67 ratings to ensure durability in washdown, marine, or outdoor industrial settings.

Why Compliance Matters

Using improperly rated lighting in hazardous locations can result in severe safety risks, regulatory violations, and potential operational shutdowns. Certified explosion proof LED lighting ensures:

-

Regulatory compliance

-

Worker safety

-

Reduced liability exposure

-

Long-term operational reliability

Proper fixture selection must always align with the classified area designation and applicable regional safety codes.

How to Select the Right Explosion Proof LED Lighting for Your Application

Selecting the appropriate explosion proof LED lighting requires more than matching brightness levels. Fixture selection must align with hazardous classification, environmental exposure, mounting conditions, and operational requirements.

1. Confirm the Hazardous Location Classification

Begin by identifying the classified area designation under applicable standards such as NEC (Class I, II, III; Division 1 or Division 2) or ATEX/IECEx Zones. The lighting fixture must carry certification equal to or greater than the classification of the environment in which it will be installed.

Never select a fixture rated for Division 2 if the area is classified as Division 1.

2. Evaluate Environmental Conditions

Consider ambient temperature, moisture exposure, corrosive materials, and vibration levels. Facilities with washdown requirements, chemical exposure, or marine conditions may require additional IP ratings and corrosion-resistant housings.

Temperature class (T-rating) must also be verified to ensure the fixture’s maximum surface temperature remains below the ignition point of surrounding hazardous materials.

3. Determine Mounting Height & Light Distribution

Mounting height significantly influences beam angle and lumen output requirements.

-

High bay installations require broader distribution and higher lumen output.

-

Low mounting positions may benefit from more controlled beam patterns.

-

Linear fixtures provide continuous coverage for corridors and process lines.

-

Flood lighting supports wide-area exterior applications.

Selecting the proper optical distribution improves uniformity and reduces dark spots or glare.

4. Calculate Required Illumination Levels

Lighting levels should align with recommended foot-candle targets for the specific industrial activity. Task-intensive areas may require higher illumination than storage or circulation zones.

Spacing layout, ceiling height, reflectivity of surfaces, and obstruction considerations all affect final fixture count and placement.

5. Verify Certification & Labeling

Ensure all explosion proof LED fixtures are clearly labeled with:

-

Class / Division or Zone rating

-

UL, ATEX, or IECEx certification marks

-

Temperature code (T-rating)

-

Voltage and environmental ratings

Documentation should be retained for compliance audits and inspections.

6. Consider Long-Term Maintenance & Efficiency

Modern explosion proof LED lighting provides substantial advantages over legacy HID or fluorescent systems:

-

Reduced energy consumption

-

Longer operational lifespan

-

Instant-on performance

-

Lower maintenance intervals

In hazardous facilities where access may be restricted or costly, long-life LED technology significantly reduces service frequency.

Strategic Approach to Hazardous Lighting Design

Because hazardous location lighting directly impacts safety and regulatory compliance, fixture selection should always be coordinated with facility engineers, safety officers, and electrical contractors familiar with classified environments.

Properly specified explosion proof LED lighting enhances operational reliability, minimizes liability exposure, and ensures long-term performance in demanding industrial conditions.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Safe, Compliant, and Engineered for Hazardous Environments

Explosion proof LED lighting is more than a product category — it is a critical safety component in regulated industrial environments. From Class I Division 1 gas locations to combustible dust zones and international ATEX-certified projects, proper fixture selection directly impacts operational safety, regulatory compliance, and long-term facility performance.

Modern explosion proof LED lighting solutions combine certified containment engineering with the energy efficiency, reliability, and reduced maintenance benefits of advanced LED technology. When properly specified, these fixtures provide durable illumination in extreme conditions while minimizing risk and liability.

Because hazardous location lighting requirements vary by industry, environment, and jurisdiction, every project should begin with a careful review of classification standards, environmental exposure factors, and mounting conditions.

Request Expert Guidance for Your Hazardous Lighting Project

If your facility requires certified explosion proof LED lighting, our team can assist with:

-

Hazardous classification review

-

Fixture type recommendations

-

Certification verification

-

Layout and illumination planning

-

Compliance documentation support

Whether you are upgrading an existing hazardous area or specifying lighting for a new industrial installation, we provide technically sound solutions designed to meet NEC, UL, ATEX, and IECEx requirements.

Contact our hazardous lighting specialists today to discuss your application and receive a compliant, performance-driven recommendation.

Available Explosion-Proof Fixtures

Get the ultimate in safety and performance for your hazardous location. Our explosion proof LED lighting solutions deliver unparalleled energy efficiency, long lifespan, and rugged reliability. When it comes to illuminating hazardous locations, prioritizing safety and performance is paramount. These hazardous location area lighting solutions are designed to meet these critical requirements, ensuring that areas prone to explosive atmospheres are equipped with the safest and most reliable lighting options available.

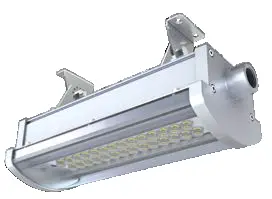

HA03

Brand: AGC

Wet and Marine Locations;

available in 30/40/50/60/70W;

up to 9,800 lumens; Prices start at $400.

C series

Brand:

Round High Bay; Up to 32,500 lumens @ 250W; Surface mounting and pendant installations; ETL: UL1598 / UL1598A / UL844 /; Class 1 Division 1, Class 1 Div 2;

60/80/100/150/200/250W;

Prices start at $400.

D series

Brand:

Square High Bay, Up to 20,250 lumens @ 150W; Prices start at $400

G series

Brand:

Small round floodlight

spherical glass diffuser and wire guard, Up to 5,400 lumens; 30/40W; Prices start at $345.

I series

Brand:

Linear Low Bay; 2ft, 4ft; Ideal for paint spray booths; UL: UL1598 / UL1598A / UL844/CSA C22.2 No.137; up to 14,000 lumens; 40/50/60/80/100W;

Prices start at $500.

L series

Brand:

Swivel hook for hanging and

hands-free operation; Portable; Plugs into standard outlets;

Battery back up for emergencies;

5/7/9/10/15/20/30W;

Prices start at $600.

MV01

Brand:

remote area light; Class 1 Div 1 fixture; up to 1,600 lumens; providing up to 10 hours of run time, weighing only 15.4 pounds; 10.8V(Battery); C100V/277V(Charger); Prices start at $850.

Class 1 Division 2 LED Lighting

A series

Brand:

High Bay Flood Light, Marine and Wet Locations; ETL: UL1598 / UL1598A / UL844; 60/80/100/150/200/250/300/400W;

Prices start at $300.

B series

Brand:

Low bay or high bay applications;

Optional Spherical Glass Diffuser;

Up to 56,000 lumens; 40/60/80/100/150/200/250/300/400W;

Prices start at $300.

H series

Brand

Low Bay Linear; 2ft/4ft fixtures; Up to 11,200; ETL: UL1598/UL1598A/UL844

CSA C22.2 No.137 / No. 250.0; Class 1 Divi 2 Groups A,B,C,D; Class 2 Div 1 Groups E,F,G, 40/60/80W; Prices start at $400

FLF series

Brand:

Low Bay Linear; 5 different lengths; for marine areas; rugged, salt water, corrosive elements; Class 1 Divi 2 Groups A,B,C,D;

up to 14,000 lumens;

10/20/30/40/50/60/70/80/90/100W;

Prices start at $300.

STA series

Brand:

Pole or wall mounted; Class 1 Div 2 Groups A,B,C,D; up to 42,000 LM; 100/150/200/300W;

Prices start at $400.

J series

Brand: CESP

small flood light; UL844 (American): UL1598 Luminaries: UL1598A Marine; UL8750; CSA; Class 1 Division 2 Group A, B, C, D,

20/30/40/60/80/100/120/150/180/200W;

Prices start at $300.

CES

Brand: Ledsion

Flood Light; 10KV surge protection; Vibration resistant tempered glass, Anti-glare; UL certified housing, suitable for marine applications; Class 1 Division 2 Group A, B, C, D

Zone1 & Zone 2 gaseous environment, Zone21;100/200W;

Prices start at $400.

ATEX / IECEX LED Explosion Proof Lighting

CPA

Brand:

Fuel pump, gas, oil station canopy

light; Ideal for Oil, Gas, and, Chemical Industry Atex II2 G EX, UL1598, UL 8750; 15″ square; up to 21,000 LM; 40/60/80/150W;

Prices start at $400.

GB

Brand: CESP

Fuel pump, gas, oil station canopy

light; Ideal for Oil, Gas, and, Chemical Industry Atex II2 G EX,; 480 mm round; up to 28,000 LM; 100/150/185/200W; Prices start at $400.

W Series

Brand:

warning device with amplifier and light; suitable for Explosion

proof environments; both marine

and on land; Prices start at $500.

GYZD81

Brand: Crowne

Obstruction Light EX; Ideal for offshore and onshore in the oil, gas and petrochemical

industries, Low Intensity and Medium Intensity models; Zone 1, 2 & 21, 22;

Prices start at $300.

Industries & Applications for Explosion Proof LED Lighting

Explosion proof LED lighting is essential across a wide range of hazardous industrial environments, including:

-

Oil and gas exploration, refineries, and petrochemical facilities

-

Chemical processing plants handling volatile materials

-

Manufacturing operations involving combustible dust or vapors

-

Grain processing and food production facilities

-

Mining operations where methane or dust hazards exist

-

Wastewater treatment plants with potential gas accumulation

-

Offshore platforms and marine installations

Each application requires careful alignment between hazardous classification, fixture rating, and environmental conditions.

Why Upgrade to LED Explosion Proof Lighting

Compared to traditional HID or fluorescent hazardous-location fixtures, LED explosion proof lighting offers:

-

Reduced energy consumption

-

Longer service life (often exceeding 50,000 hours)

-

Lower heat output

-

Improved durability under vibration and extreme temperatures

-

Reduced maintenance in hard-to-access classified areas

In hazardous environments where downtime and safety risk carry high costs, LED technology provides both operational efficiency and long-term reliability.

Frequently Asked Questions About Explosion Proof LED Lighting

1. What is the difference between Class I Division 1 and Division 2 lighting?

Class I Division 1 lighting is required in environments where flammable gases or vapors are present under normal operating conditions. Class I Division 2 lighting is used in areas where hazardous materials are only present under abnormal conditions, such as equipment failure or accidental release. Fixtures must match the exact classification of the installation area.

2. Does explosion proof mean the fixture is waterproof?

No. Explosion proof refers specifically to the fixture’s ability to contain internal ignition sources and prevent sparks from igniting surrounding hazardous atmospheres. Waterproof protection is determined separately by the fixture’s IP rating (such as IP66 or IP67).

3. Are explosion proof LED lights required in all hazardous areas?

Explosion proof LED lighting is required only in classified hazardous locations as defined by NEC, OSHA, or ATEX/IECEx standards. Proper classification review is necessary before selecting a fixture.

4. What certifications should explosion proof LED lighting carry?

Certified explosion proof LED lighting may carry UL844 certification in North America, ATEX certification in the European Union, or IECEx certification internationally. Fixtures must also list their Class, Division, Zone, and temperature code ratings.

5. How long do explosion proof LED fixtures last?

Most explosion proof LED lighting fixtures are rated for 50,000 hours or more. The extended lifespan reduces maintenance frequency, especially in hazardous environments where fixture access may require shutdown procedures or safety protocols.

Certified Lighting for Hazardous Industrial Environments

From Class I Division 1 to Zone-rated applications, our explosion-proof LED lighting solutions are engineered for safety, durability, and long-term performance in demanding environments.