Explosion-Proof Lighting for Hazardous Industrial Environments

Explosion-proof lighting is engineered for use in hazardous environments where flammable gases, vapors, dusts, or fibers may be present. These fixtures are constructed to contain internal ignition sources and prevent sparks or heat from igniting surrounding atmospheres. Explosion-proof LED lighting is commonly specified in industrial facilities to improve safety, ensure regulatory compliance, and deliver reliable illumination in extreme operating conditions.

This guide explains when explosion-proof lighting is required, typical technical specifications, and how fixtures are selected for hazardous location applications.

When to Use Explosion-Proof Lighting

Explosion-proof lighting is specified for environments where combustible materials may be present during normal or abnormal operating conditions, including:

-

Areas classified as hazardous locations under industrial safety standards

-

Facilities handling flammable gases, vapors, or combustible dust

-

Industrial processes involving chemicals, fuels, or volatile materials

-

Locations requiring code-compliant containment of ignition sources

-

Operations where fixture reliability is critical under harsh conditions

Explosion-proof fixtures are selected not for brightness alone, but for their ability to operate safely within classified environments

Explosion-Proof Fixture Types by Application

Typical Explosion-Proof Lighting Specifications

Typical Wattage: 30W–300W depending on application and mounting height

Lumen Output: Application-specific high-output LED configurations

Hazardous Location Ratings: Class I, Class II, or Class III

Division / Zone Ratings: Division 1 / Division 2 or Zone 0 / Zone 1 / Zone 2

Construction: Heavy-duty aluminum or stainless steel housings

Certifications: UL, ETL, ATEX, IECEx (application dependent)

Ingress Protection: IP66 or higher for dust and moisture resistance

| Classification | Environment Type | Typical Examples |

|---|---|---|

| Class I | Flammable gases or vapors may be present | Refineries, fuel storage, paint spray areas |

| Class II | Combustible dust environments | Grain handling, food processing, metal dust |

| Class III | Ignitable fibers or flyings | Textile manufacturing, woodworking |

| System | Concept |

|---|---|

| Division | Based on likelihood of hazardous material presence during normal operations |

| Zone | Defines probability and duration of hazardous atmosphere exposure |

| T-Rating | Maximum Surface Temperature |

|---|---|

| T1 | High allowable temperature |

| T3 | Moderate limitation |

| T5 | Strict limitation |

| T6 | Very low maximum surface temperature |

Fixture temperature codes must always be equal to or lower than the ignition temperature of the hazardous material present.

| Feature | Explosion-Proof | Vapor-Tight |

|---|---|---|

| Internal ignition containment | Yes | No |

| Hazardous location approval | Yes | No |

| Dust / moisture protection | Yes | Yes |

| Intended for classified areas | Yes | No |

Explosion-Proof Lighting Planning & Selection

How is explosion-proof lighting specified for hazardous areas?

Explosion-proof lighting is specified based on the hazardous classification of the space, including the type of combustible material present and the likelihood of exposure. Fixture certifications, enclosure design, and temperature ratings are evaluated to ensure the luminaire does not become an ignition source under normal or fault conditions.

What is the difference between explosion-proof and vapor-tight lighting?

Explosion-proof fixtures are designed to contain internal ignition events and prevent flame propagation into hazardous atmospheres, while vapor-tight fixtures are intended to resist moisture, dust, and corrosion. Vapor-tight lighting does not provide the containment required for classified hazardous locations.

How are wattage and lumen output determined for explosion-proof fixtures?

Wattage and lumen output are selected based on mounting height, task requirements, and environmental conditions. In hazardous locations, fixture performance must also account for thermal management and operating temperature limits to maintain safety and compliance.

When is a hazardous area classification review required?

A hazardous area classification review is recommended whenever combustible materials are present or when facility processes change. This evaluation determines the appropriate class, division, or zone rating and ensures lighting equipment is properly specified for the environment.

Common Applications

Explosion-proof lighting is commonly used in:

-

Oil and gas production and processing facilities

-

Chemical manufacturing and storage areas

-

Refineries and petrochemical plants

-

Grain handling and dust-prone industrial sites

-

Paint booths, fuel storage, and solvent handling areas

-

Wastewater treatment and industrial utility zones

Get the ultimate in safety and performance for your hazardous location. Our explosion proof LED lighting solutions deliver unparalleled energy efficiency, long lifespan, and rugged reliability. When it comes to illuminating hazardous locations, prioritizing safety and performance is paramount. These hazardous location area lighting solutions are designed to meet these critical requirements, ensuring that areas prone to explosive atmospheres are equipped with the safest and most reliable lighting options available.

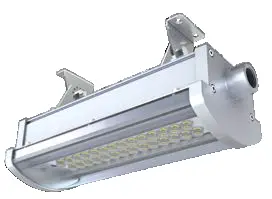

HA03

Brand: AGC

Wet and Marine Locations;

available in 30/40/50/60/70W;

up to 9,800 lumens; Prices start at $400.

C series

Brand:

Round High Bay; Up to 32,500 lumens @ 250W; Surface mounting and pendant installations; ETL: UL1598 / UL1598A / UL844 /; Class 1 Division 1, Class 1 Div 2;

60/80/100/150/200/250W;

Prices start at $400.

D series

Brand:

Square High Bay, Up to 20,250 lumens @ 150W; Prices start at $400

G series

Brand:

Small round floodlight

spherical glass diffuser and wire guard, Up to 5,400 lumens; 30/40W; Prices start at $345.

I series

Brand:

Linear Low Bay; 2ft, 4ft; Ideal for paint spray booths; UL: UL1598 / UL1598A / UL844/CSA C22.2 No.137; up to 14,000 lumens; 40/50/60/80/100W;

Prices start at $500.

L series

Brand:

Swivel hook for hanging and

hands-free operation; Portable; Plugs into standard outlets;

Battery back up for emergencies;

5/7/9/10/15/20/30W;

Prices start at $600.

MV01

Brand:

remote area light; Class 1 Div 1 fixture; up to 1,600 lumens; providing up to 10 hours of run time, weighing only 15.4 pounds; 10.8V(Battery); C100V/277V(Charger); Prices start at $850.

Class 1 Division 2 LED Lighting

A series

Brand:

High Bay Flood Light, Marine and Wet Locations; ETL: UL1598 / UL1598A / UL844; 60/80/100/150/200/250/300/400W;

Prices start at $300.

B series

Brand:

Low bay or high bay applications;

Optional Spherical Glass Diffuser;

Up to 56,000 lumens; 40/60/80/100/150/200/250/300/400W;

Prices start at $300.

H series

Brand

Low Bay Linear; 2ft/4ft fixtures; Up to 11,200; ETL: UL1598/UL1598A/UL844

CSA C22.2 No.137 / No. 250.0; Class 1 Divi 2 Groups A,B,C,D; Class 2 Div 1 Groups E,F,G, 40/60/80W; Prices start at $400

FLF series

Brand:

Low Bay Linear; 5 different lengths; for marine areas; rugged, salt water, corrosive elements; Class 1 Divi 2 Groups A,B,C,D;

up to 14,000 lumens;

10/20/30/40/50/60/70/80/90/100W;

Prices start at $300.

STA series

Brand:

Pole or wall mounted; Class 1 Div 2 Groups A,B,C,D; up to 42,000 LM; 100/150/200/300W;

Prices start at $400.

J series

Brand: CESP

small flood light; UL844 (American): UL1598 Luminaries: UL1598A Marine; UL8750; CSA; Class 1 Division 2 Group A, B, C, D,

20/30/40/60/80/100/120/150/180/200W;

Prices start at $300.

CES

Brand: Ledsion

Flood Light; 10KV surge protection; Vibration resistant tempered glass, Anti-glare; UL certified housing, suitable for marine applications; Class 1 Division 2 Group A, B, C, D

Zone1 & Zone 2 gaseous environment, Zone21;100/200W;

Prices start at $400.

ATEX / IECEX LED Explosion Proof Lighting

CPA

Brand:

Fuel pump, gas, oil station canopy

light; Ideal for Oil, Gas, and, Chemical Industry Atex II2 G EX, UL1598, UL 8750; 15″ square; up to 21,000 LM; 40/60/80/150W;

Prices start at $400.

GB

Brand: CESP

Fuel pump, gas, oil station canopy

light; Ideal for Oil, Gas, and, Chemical Industry Atex II2 G EX,; 480 mm round; up to 28,000 LM; 100/150/185/200W; Prices start at $400.

W Series

Brand:

warning device with amplifier and light; suitable for Explosion

proof environments; both marine

and on land; Prices start at $500.

GYZD81

Brand: Crowne

Obstruction Light EX; Ideal for offshore and onshore in the oil, gas and petrochemical

industries, Low Intensity and Medium Intensity models; Zone 1, 2 & 21, 22;

Prices start at $300.

Why LED Explosion Proof Lighting? The Benefits:

- Robust Design: Built to withstand harsh industrial environments and potential hazards.

- Superior Efficiency: LEDs significantly reduce energy consumption, lowering long-term operating costs.

- Extended Lifespan: LEDs offer an exceptionally long lifespan, minimizing replacement frequency and maintenance downtime.

Technical Details

- Explosion Proof Ratings: Understanding ATEX and UL 844 standards is crucial for selecting the correct fixture for your hazardous environment. Read more about The Essential Guide to Explosion-proof Lighting Fixtures here.

- Zone and Class Designations: Specific light fixtures are designed to address the risks posed in Zones 0-22 (flammable gases) and Class 1 – 3 locations (combustible materials).

LED Explosion Proof Lights in the Field

- Class 1: Containment Specialists: These lights are essential in areas where flammable vapors or gases may be present, ensuring any potential ignition is safely contained.

- Class 2: Protecting Against Dust Hazards: Designed to prevent dust particles from becoming a combustible hazard in sensitive environments.

Summary: Safety and Sustainability

LED Explosion Proof Lighting prioritizes workplace safety and responsible energy use. These specialized fixtures provide robust illumination in hazardous environments, helping industries reduce risk and operate more efficiently. By investing in this technology, we create a safer, more sustainable industrial future.

FAQs: Providing Comprehensive Responses to Your Inquiries

Q: Are these lights durable enough to withstand rough conditions and continue operating effectively?

A: Indeed, they are exceptionally durable, designed with robustness in mind, yet they provide illumination comparable to the most renowned architectural landmarks.

Q: Is the energy consumption of these lights high enough to significantly increase my electricity bills?

A: Absolutely not. The LED technology employed in these lights is designed for efficiency, consuming minimal power, thus ensuring your energy bills remain low.

Q: How frequently will I need to replace the bulbs?

A: The necessity for bulb replacement is remarkably infrequent. Thanks to LED technology, these bulbs have an extended lifespan, reducing the need for frequent replacements.

Understanding Explosion Proof Lighting: Your Essential Safeguard

In industries where flammable gases, vapors, dust, or fibers pose a potential explosion risk, specialized lighting is critical. Explosion-proof lights are carefully made to stop sparks or heat from causing fires in the area around them. This robust construction ensures maximum safety in hazardous locations. Read more about Understanding LED Explosion Proof Lighting

Why LED Explosion Proof Lighting is the Superior Choice

While traditional explosion-proof lights offer a baseline of protection, LED technology takes this safety to the next level. Here’s why upgrading to explosion-proof LEDs is a smart investment:

- Unmatched Energy Efficiency: LED explosion-proof lights consume significantly less energy than incandescent or fluorescent alternatives, leading to substantial cost savings over time.

- Exceptional Lifespan: LEDs boast an incredibly long lifespan, often exceeding 50,000 hours. This translates to less frequent replacements, reduced maintenance, and minimized downtime.

- Minimized Heat Output: LEDs generate far less heat than traditional bulbs, further reducing the risk of accidental ignition in hazardous areas.

- Explosion-proof LED lights can be mounted on ceilings, and walls, or used as portable fixtures, offering unmatched flexibility in design. This allows you to tailor the lighting perfectly to your specific hazardous environment and task needs. read more about Shining a Light on Safety: Your Guide to Explosion Proof Drop Lights here.

- Enhanced Durability: Designed to withstand the rigors of demanding industrial settings, LED explosion-proof lights offer superior resistance to shock, vibration, and extreme temperatures.

Where Explosion Proof Lighting Makes the Difference

Explosion-proof lighting is indispensable in numerous industries and applications:

- Oil and Gas: Exploration platforms, refineries, petrochemical plants, fuel depots, and anywhere flammable gases or liquids may be present.

- Chemical Processing: Facilities handling volatile solvents, reactive chemicals, and other potentially hazardous materials.

- Manufacturing: Industrial settings with combustible dust (grain, wood, metal, etc.), flammable vapors, or ignitable fibers.

- Mining: Underground and surface mines where methane gas or coal dust pose explosion risks.

- Wastewater Treatment: Plants where flammable gases can accumulate.

- Other Hazardous Locations: Any area classified as Class I, Division 1 or 2, where ignitable substances are regularly present or likely to occur under abnormal conditions. Read more about Mitigate Dangers with LED Explosion Lights here.

The Importance of Choosing the Right Explosion Proof Lighting

Not all explosion-proof lights are created equal. Here’s what to consider when selecting the right fixtures for your needs:

- Hazardous Area Classification: Ensure the fixture is rated for the specific class, division, and gas group present in your environment.

- Lumens: Choose a brightness level appropriate for your workspace needs.

- Beam Angle: Select fixtures that provide the ideal light distribution pattern.

- Mounting Options: Determine whether ceiling, wall, or portable fixtures are most suitable.

- Certification: Always choose fixtures with certifications from reputable agencies (UL, ATEX, IECEx).

Let Us Power Your Safety and Efficiency

Browse our extensive selection of explosion-proof LED lights, lamps, and fixtures. We’re committed to providing the highest quality lighting solutions for any hazardous environment. Contact us today; our experts will help you find the perfect explosion-proof lighting to maximize safety, productivity, and cost-effectiveness in your facility.

By Steven Wilson – First Published on:July 28, 2015